|

Electrical Spec. |

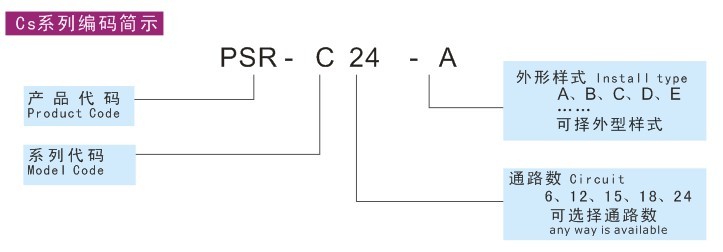

Options | ||

|

Circuit |

24 |

Support for higher speed:500Rpm |

|

|

Rating voltage |

240VAC |

More install method for option |

|

|

Rating current |

2A/Ring,5A,10A by parrelled |

Lead length can be appointed |

|

|

Insulation resistance |

1000MΩ@500VDC |

Cable Exit is optional |

|

|

Dielectric strength |

600VDC@50Hz |

Available connecter and Heat-shrink tube |

|

|

Electrical noise |

10mΩ@6VDC,50mA, 5Rpm |

|

|

|

Mechanical Spec |

Environment |

||

|

Speed |

300Rpm |

Working temperature |

-40℃~+80℃ |

|

Torque |

0.01N.M |

Mechanical vibration |

MIL-SID-810E |

|

Seal class |

IP54 |

Humidity |

10% to 90% RH non-condensing |

|

Contact material |

Precious Metal:Gold-Gold |

Materials |

Lead Free,RoHS compliant |

|

Lead Wire |

24 color AWG#28 Teflon wire |

CE Certified |

YES |

|

Life |

30million revolutions |

|

|

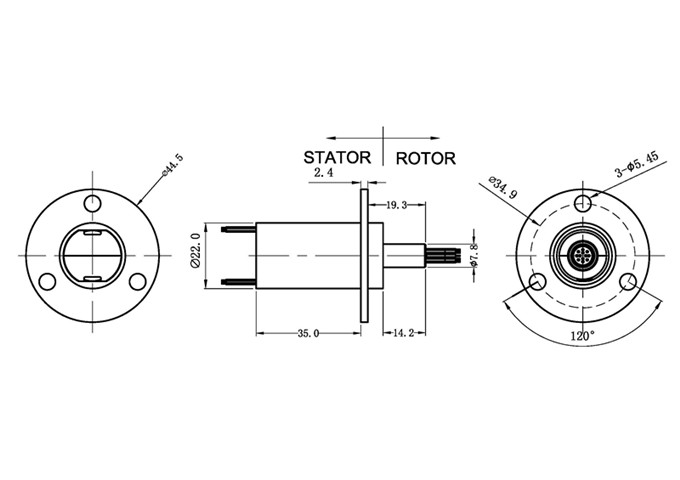

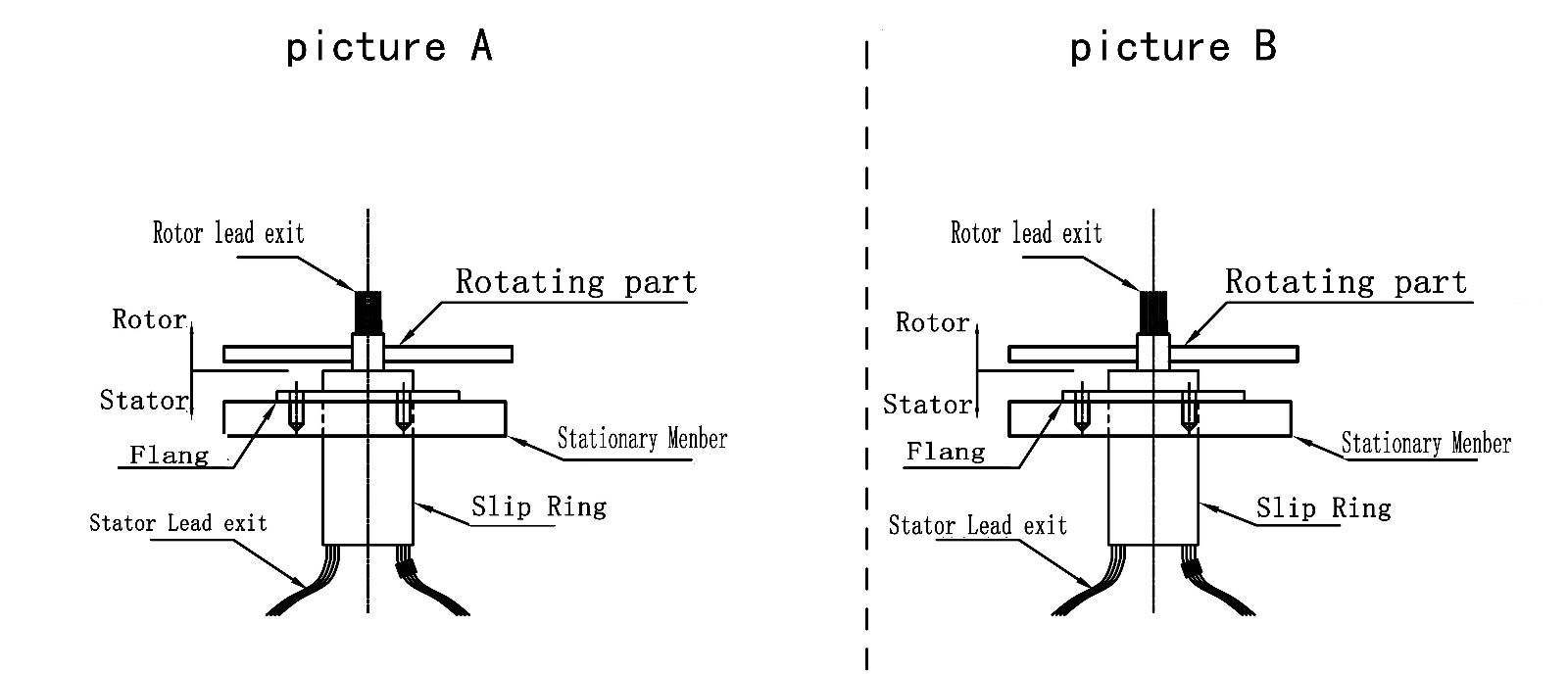

Installation Guide:

Picture A

1.Position the slip ring in the desired location and tighten both set screws to the shaft.Maximum torque 25Ib-in(DO NOT OVER TORQUE)

2.Route the wiring and make the neccessary connections.Do not allow the wiring to restrict free rotation of the slip ring.Do not constrain wiring such that wire flexing occurs.Doing so will ultimately cause failure(breakage of the wiring).

Picture B

1.Align the mouting holes(M3X8)in the flange to mouting base and install mouting screws(M3),securely tighten screws.

2.Route the wiring and make neccessary connections.Do not allow the wiring to restrict free rotation of the slip ring.

CAUTION:

Because of possible geometric mismatching between the customer's application and the slip ring,'hard mouting'of both ends of the slip ring(i.e.securing the rotor and stator such that there is no floating during operation) is not recommended and may cause premature failure.